Everything You Need to Know About Replacing Intake Manifolds, Manifold Air Pressure Sensors, and Fuel Injectors

Many parts in your vehicle work together in order to ensure your engine gets the right fuel-to-air ratio.

One of the most important is your intake manifold, which distributes fuel from the engine’s carburetor to each cylinder. When this part wears out, it can cause several issues, including poor performance and overheat.

This component is crucial in controlling airflow into each cylinder. Made from durable metal, it attaches to the engine block and has passages for fuel and air.

These passages are located between each of the cylinders so that when a piston moves up, it draws in fuel and air from its specific passage.

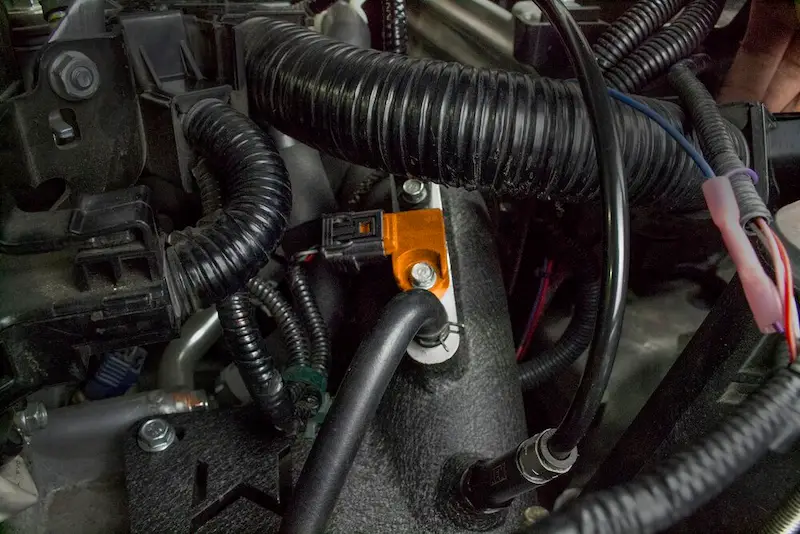

Then, there’s the MAP sensor, which is also located in the intake manifold. This sensor measures air pressure and sends that information to the engine’s computer which determines how much fuel should be delivered. If this sensor fails, your vehicle may not get enough fuel or it could overheat due to a lack of coolant flow.

The MAP sensor is usually placed on top of the intake manifold so you’ll want to make sure you’re buying one made specifically for your vehicle. Not only will it fit perfectly, but it will work properly as well.

Your vehicle’s engine requires a certain amount of air pressure to function properly and this is what helps give it the power needed for acceleration as well as maintaining fuel efficiency at cruising speeds. If there’s too much or too little, your engine won’t be able to perform its duties correctly. This is why it’s important to have a properly functioning intake manifold along with other components such as a performance exhaust system, which will improve airflow.

Replacing Your Intake Manifold

When replacing your intake manifold, it’s best to work on it in a well-lit area. Many of the parts are small and can be easily lost or misplaced if you’re not careful. You’ll want to disconnect all the hoses from the manifold before removing them from the engine block.

If there are any vacuum lines attached, make sure they don’t get tangled up with any other components while removing them.

Next, use something sharp like a screwdriver to pry off the manifold as it may have some adhesive underneath it. Make sure you clean the area where it was attached thoroughly before installing the new one as even a small particle can cause problems later on.

Now, install the new manifold and make sure all of the hoses are connected properly. The vacuum lines should be placed back into their original positions and tightened with an adjustable wrench or socket set.

Next, check to see if there’s any residue left over from when you removed the old part. If so, use some carb cleaner to get rid of it and then spray with water to dry off the area.

Replacing Your MAP Sensor

To check if your vehicle’s MAP sensor is working properly, you’ll need to turn on the ignition and wait until the engine has reached operating temperature. With a scan tool or diagnostic tool connected to your vehicle’s computer system, look for any codes relating to cylinder four.

If there are no codes present, this means that the MAP sensor is functioning normally. If there are codes related to cylinder four, it means that the sensor has failed and needs to be replaced.

When choosing replacement MAP sensors, it’s important to get one that’s made by a reputable manufacturer as this will ensure its longevity. You’ll also want to check the part number of your current sensor and compare it with what’s listed on the box of the new one before buying. This will help you get the right fit for your vehicle.

Once installed, you can use a scan tool or diagnostic tool again to see if there are any engine trouble codes present. If so, you may need to do some additional work such as checking the wiring or replacing the computer. If there are no codes, this means that the sensor is working properly.

Replacing Fuel Injectors

If you still aren’t getting the right fuel-to-air ratio, then perhaps you have a problem with the fuel injectors. Fuel injectors are responsible for delivering the right amount of fuel to each cylinder.

If they fail, then your vehicle will have issues with poor performance and it may not idle properly.

Next, if there are any bolts that hold down the intake manifold, remove them and place them in a cup or container. Next, remove the intake manifold from the vehicle. It’s best to do this in a well-lit area so you can clearly see where each component belongs.

Do not touch the injectors as they’re very delicate and can easily break if handled too roughly. Instead, use a flathead screwdriver to pry them out. If there are any seals or gaskets that need replacing, make sure to get them from the box of your new fuel injectors.

When buying replacement fuel injectors, it’s important to make sure that they are compatible with your vehicle. Here are the factors that determine injector compatibility and how to check if the replacement parts will work in your car or not.

A common reason why some injectors may not be compatible is that they were made for another vehicle. As a general rule, auto parts manufacturers tend to make parts that are compatible with their own products. Therefore, it’s important to look at the make and model of your current fuel injectors before buying replacements.

The first thing to check is the manufacturer’s logo on your current injectors. If they have a sticker that says “made by” then the manufacturer, it’s safe to buy compatible replacement parts from them. Another way of checking compatibility is by looking at the type of fuel injector you currently have.

There are two types of fuel injectors: mechanical and electronic. Electronic ones are more complicated and therefore require special care when replacing or repairing. You should only replace them with electronic injectors that have the same voltage and current rating as your vehicle’s original components.

Another factor that determines injector compatibility is its type. There are two types of fuel injectors: direct and port injected.

Direct-injected ones are mostly used in newer cars while port injected are common on older vehicles. To check if your replacement parts are compatible, you should do a careful inspection of all the parts of your fuel system.

Lastly, install the new fuel injectors and make sure they’re properly secured with an adjustable wrench or socket set.

You’ll also want to check for leaks after installing them by spraying some soapy water onto the engine block. If you see bubbles forming around the injector’s connection point, then it means there’s a leak in its seal.

Then, spray some soapy water onto the cylinder heads and make sure there are no bubbles forming around the injector’s connection point.

If there is, then you may have a problem with its wiring harness or it needs to be tightened further.

Joe lives and breathes cars and trucks. After many years working in the Auto industry, he decided that it is only right to share his knowledge with the public. As a qualified expert in trucks and cars, he started working for Truckile.com and is the main editor and publisher.